My cousin invites me to a softball game –the teams were from local corporations in OakBrook — Chicago Bridge & Iron, R. H. Donnelly printing, McDonalds.

He let me know that there was an opening in the mailroom and with my US Govt mail experience, he thought I’d be a shoo in for a mailroom slot: now, its not as exciting as it sounds — but it was easy, indoors, and pay was decent. Circa 1974 (Note: one mailroom alum went on to be chairman: M Quinlan)

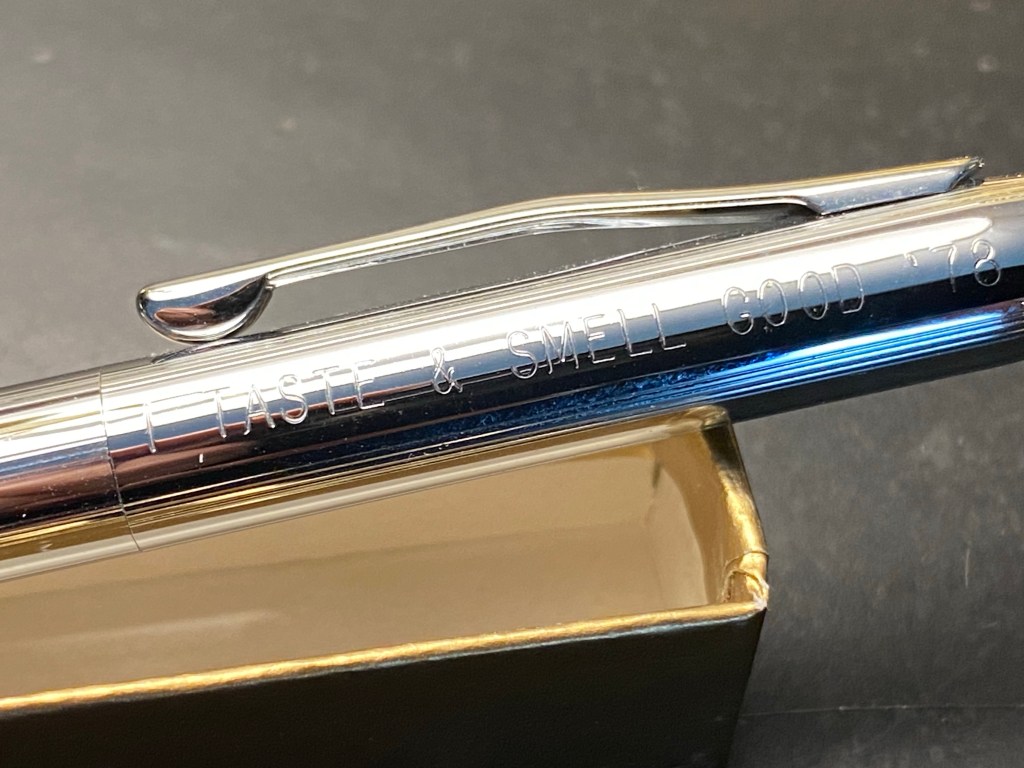

As to the title of this article , I joined the taste panel soon after starting. We’d test 3 samples and see if we could tell a difference: I was apparently very accurate.

They sent me to training so we could evaluate and be on same scale when describing what we were tasting. We were taught to look for first taste, mouth feel, levels of sweet/sour/bitter, finish. I spent years working on a new tartar sauce. You’re welcome. 🙂

I was awarded the pen as a bit of recognition. The best part was I could tell people I was a top tongue ( this helped when I cooked at Charlie Trotters)

So, id deliver mail by day, and take night courses to chip away at college. not bad.

At the time, we’d start when everybody else did — and so mail wouldn’t hit the desks until after 10or later — i’m sure it wasn’t my idea but I shared with my supervisor that at the USPO we’d start sorting at 6am so we could deliver mail to the businesses first thing: why not apply that to HQ: so I’d go in early (7am) and sort most of the mail so it was ready for delivery at 8:30 as the admins arrived.

It was my first experience with process improvement — it made a difference.

i had taken computer courses as part of my associates: degree ( punch cards, sort boards, tapes. all incredibly outdated but fascinating. The mailroom was in a room next to the computer room: a massive IBM 360/370 computer, raised floor, glass walls. I worked week ends, open nights: loading green bar paper to feed giant line printers — W-2 season was weeks of overtime. I worked there so much we had the nick name Otters (for OT). My girlfriend would bring dinner and a beer for us in the computer room. Amazing — she was very patient…then one day poof.

One of my regular overtime stints was to work in the Report Distribution room. Boxes of printed green bar paper with six layers of computer 8.5 x 14 paper and 5 layers of carbon paper. The main stack was loaded on one end and then threaded through the decolator to separate the copies from the carbon paper — the paper folded into a new stack and the carbon was on a spool. each stack then was fed through an electro static device called a “burster” — that would separate the pages at the perforation.

: we used to line the burster right behind the decolator and we’d thread the top copy to the burster thus saving on one stack … but getting the speed calibrated on the two devices was nerve racking to say the least — but man were we wired on cherry Coke.

Computer rooms of the day were sealed to minimize dust and control temperature — and equipped with cylinders of Halon — a fire extinguisher on steroids. One day, an exec is getting a tour, nodding and just dying to touch the computer– so on his way out he looks at the red button near the glass door — and while i think he thought it was a door opener – he says, “What’s this button do?” and proceeds to press it — holy hell breaks loose: halon puts out fires by eliminating oxygen to protect the computer system fast and without water — you have 30 seconds to GET THE F___ OUT! before we all suffocated. and as we all run for the door the room fills with the cloud of death (as we later dubbed it).

I was about to leave the floor one friday night and someone from exec suite came down with something for the CIO — and they were hoping someone in mailroom (long gone) or computer room — that would be me — would take it to him (this was before fedex and messengers)…so i said id run it out. i knocked, gave him the envelope, he asked my name — and he headed to his dinner and i to bed as i worked on Saturdays.

But the Invisible Hand was at work. soon after, i was asked to join an experimental team using real-time computing and FORTRAN to build new systems for the stores. the team was led by an ex marine, a nuclear mathematician. The team then consisted of two really smart programmers. i accepted — i wasnt looking but i wasnt sure what my plan was so this was a gift.

the mission of the team was to build real time computer programs using remote Honeywell computers and a National dial up network (both provided by a division of General Electric). We deployed Texas Instruments Silent 700s with 300 baud acoustic couplers and thermal printing.

The programs were written in FORTRAN IV

the programs were

1) cash management;

2) food cost

3) time clock

4) labor scheduling

cash management was important for two reasons: 1) helping the manager reconcile the cash drawers to identify cash over/short; 2) calculate the days deposit. The later had the biggest impact: we’d prompt the store manager to enter key cash metrics and then because all stores were reporting on a centralized network, the company could issue electronic withdrawals same night. Over 1600 stores, an average of $2,000 a day —- the company used to wait 2-4 days— the payback was huge: Corp got the cash and the manager got key metrics.

foodcost was important. Margins were thin so any waste or shrinkage had impact. Our programs would “explode” the finished product sold into component parts and then compare usage to remaining inventory. Previously was done monthly but 30 day averages hid a lot of issues: but calculating daily using a computer really made inventory management possible.

labor scheduling was a modeling program… we relied on queuing theory (lots o math)…start with sales by hour and we could suggest staffing . Prior to this it was a manager sitting in the front manually preparing a schedule. Time consuming, took manager off the floor, and wasn’t very accurate. We could make recommendations and manager could adjust.

the time clock was huge: each store had a clock and time cards… and a bookkeeper who’d calculate the hours. Time consuming, expensive, errors, labor issues.

so Panasonic designed a clock with an optical reader that would store an employee’s punches. At the end of the day The program would read the clocks memory and calculate the differences. It was my program.

we had some tricky bits:

- I had to store punches in pairs: clock in and clock out — but differentiate between break punches from shift, and I had to identify and project for missing punches. I used a Fortran based 8 vector array( try thinking beyond 3d) to store and sort and calculate;

- cpu usage was expensive so we performed bit manipulation to use 16bits of 4bytes…we were manipulating the “core”

- as a fun side note, FORTRAN relied on parentheses to determine order of processing… it was hard to get them correct first time. I wrote the longest line of FORTRAN code that compiled on first time, we cheered, we opened beer, we framed the line. My boss shook my hand and said it was amazing…”now break it up so we could maintain it”. Keep it Simple. We were pretty geeky.

- We had some user adoption issues that we had to address: first, people had a problem with the clock — not knowing when a punch was recorded… and we’d get too many as they inserted their tine card multiple times – lights flashing; and the help sheet wasn’t helping. For the first, a mechanical device was added to each clock that made a ka-chunk sound like a manual one. For the later, I was talking to a Mexican restaurant owner —- I explained and he said that overall they couldn’t speak English and couldn’t read Spanish let alone understand the very formal Berlitz translation we used. We added photos and used a more local translation —- it worked. Errors dropped.

- we thought a pc would be next step.. Dec pdp-11 was available but grease in the air messed with disk drives.

- the stores ended their work week on Saturday night. If there was a problem, every store would get it and 1600 calls would follow as it rolled across time zones unless we as programmers could fixit after getting just a couple of reports. I was asked/volunteered to work Sunday morning at 6am to take support calls. We also had a rule that if your program was running a new version you had to man the phones with me. Most sundays were quiet.

- We also had access to lots of data. One half day Friday we were in the first floor bar The Wellington. Vodka gimlets. The head of American operations was talking about how long it took to get a weekly sales number total, comparable, and Inc/dec prior week, prior year. I said I could do that before the bar tab arrived. And I came down with a flash report…I thought I was showing the strength of what we had built.. mis management was not happy… as it was such a raw number… I later explained to him that it was a raw number … but he brushed it aside. I learned to be less impulsive.

I’ve had a golf club in hand often…here, we can see where my grip issues began…

here is a photo of my foursome— I think I haven’t resolved my fashion priorities.

- I teed off and my ball only made it past the front tees… so I walked up to my ball and was about to swing — when the starter says “you must take your first shot from the tee box” … so in front of 100 people i had to yell back, “but this is my second shot”… yikes

- later that night, we were eating in a octagonal room where the walls looked like doors. Behind a some were access to restrooms, some hid the walk up bar. I got up to go no to the bathroom but all the doors were locked. So I was pulling on doors while our ceo was speaking..”mr petersen, please sit down… the bars are closed”…whoops. Years later at a former colleagues retirement party the then past chairman pulled on a locked door… he could be heard “ bar closed? Hey petersen knows how to do this…” some 30 years later.

We had a receptionist who would welcome v everyone — I chose to strap on a battery and red bulb… (see if you can find it) and I still have the pants…

I loved programming and the company.

We’d visit/work in the stores occasionally — on store day everybody went to a store; I was writing systems fir in store use so did so every quarter.

We had lots of swag.

Later, I was assigned to deploy ibm 8100 distributed computers… and learning more assembler…but was getting a bit bored. I realized if I stayed as a programmer I’d either stay with a technology that woujd eventually be obsolete; or have to keep learning new ones. I knew I was headed for consulting.

When I left, I think I was pretty noisy— about it. Scarred, loss of friends. I’m not sure why, but I printed a good bye card and was given the anonymous note…

/i I learned alot about real time computing, roi, quality, operational excellence, team work, evolving technologies, user adoption, & problem solving. It was heady times as McDonald’s grew… as did my confidence.

PS: In case you were wondering about how we did in softball… where this all started? We were 1976 champs!

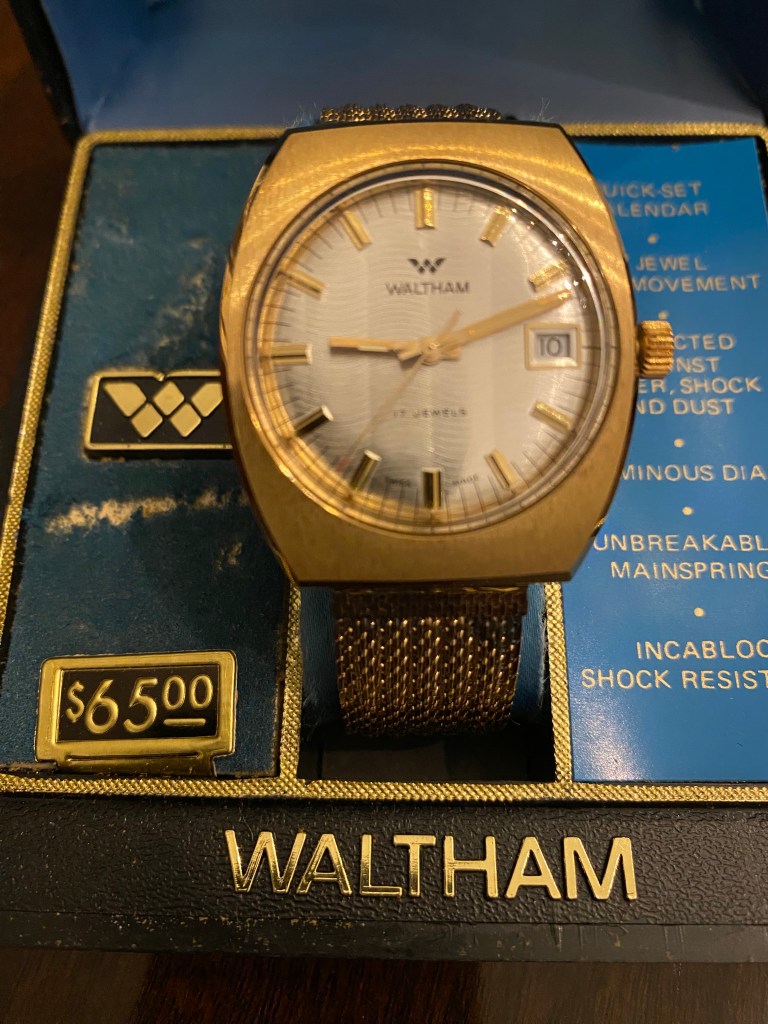

and I got a cool watch… very retro

Leave a comment